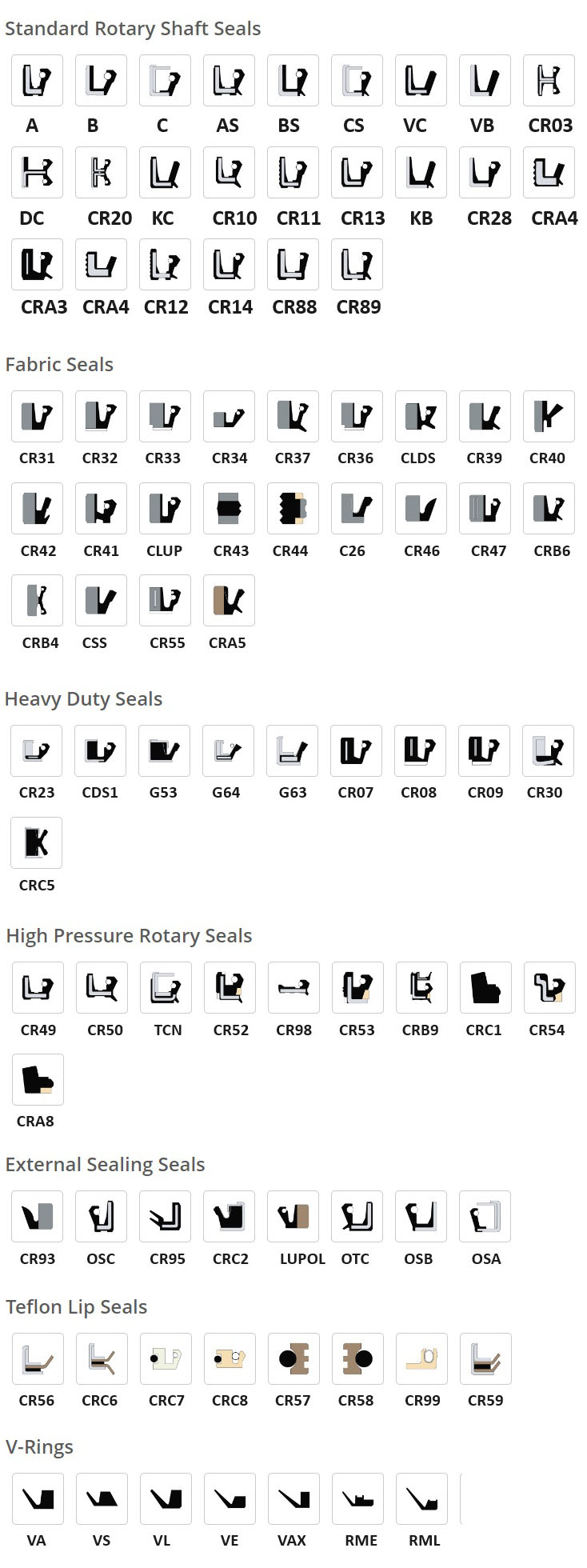

Rotary Shaft

Seals

Radial shaft seals, also known as lip seals or oil and grease seals, are used to seal rotary elements, such as a shaft or rotating bore. Common examples include strut seals, axle seals, power steering seals, truck seals, and valve stem seals. The use of modern elastomers has greatly increased the range of uses for these seals. The use of a garter spring helps the sealing lip compensate for lip wear and elastomer material changes.

The seal construction consists of a spring-suspended main sealing lip, which has a point contact point with the shaft. Different types of dust lips can be used to exclude contaminants. Elastomers like FKM, ACM, NBR, HNBR, VMQ, and EPDM are common. Teflon can be used in pharma, food & beverage industry. Durometers range from 70 to 85 Shore A.

Colonial Seal Company has over 25,000 mold sizes in inch or metric. Custom seals can be manufactured using programmable lathes or metal spinning processes. We also offer design, sampling and testing services, along with cost-effective replacements for old or discontinued seals, with cross-reference capability for large rotary shaft seal producers. 10 to 20% savings.

In the last 26 years, we have supplied replacement or equivalent seals to the following original equipment manufacturers (OEMs): SKF/Chicago Rawhide seals, National/Federal Mogul Oil seals, Freudenberg seals, Garlock® seals, Timken® seals, Johnsville seals, Clipper-Parker seals, NoKn seals, and Trostel seals