Probably the most critical design feature of any rotary seal design is the contact point or interface between the sealing lip and application shaft or housing if it’s an external seal. Typically, the sealing lips are made of an elastomeric material such as NBR, Viton, PTFE, etc.

Apart from the elastomeric lip material, a critical design feature of the rotary seal lip is its geometry. Lip geometry is one of several factors that directly affect the radial load exerted on the shaft. The others include the presence of a garter spring, shaft finish, pressure, and installation. Since the inner diameter of a seal is manufactured to be slightly smaller than the shaft diameter, the elastomeric lip will be stretched outward by the shaft. When a garter spring is added to the seal, these two forces contribute to increasing the load on the shaft. Two lip measurements that contribute to the radial load force include the beam or lip length measured as the parallel distance between the point where the lip contacts the shaft and the thinnest part of the beam. Another factor contributing to the radial load on the shaft is the beam or flex thickness. Flex thickness – the width of the area between the sealing lip and heel of a shaft seal. This width should be thick enough to prevent the lip curling back on itself but thin enough to allow follow-ability. This measurement has direct influence on the radial load force or pressure on the shaft. For instance, for any fixed beam thickness a longer lip length will exert less load force on the shaft than a shorter lip length. Conversely, for the same beam thickness a shorter lip length will exert more force on the shaft. Given the above criteria, a shorter lip will also experience increased friction and wear than a longer lip. It also follows that for a fixed lip length any increase in flex thickness will result in increased radial load force on the shaft whereas decreasing the flex thickness will reduce the radial load force. In general, the beam should be thick enough to prevent torsional distortion and thin enough to allow flexibility. In high-pressure applications, shorter lips are preferred because they have higher resistance to deformation. For shafts with eccentricities such as shaft to bore misalignment or dynamic run out, longer lips are preferred because they are more flexible resulting in superior follow-ability. Follow-ability is the ability of the sealing lip to maintain contact with the shaft under dynamic run-out conditions. The ideal lip can only be determined by evaluating several interrelated factors including shaft speed, presence of eccentricities, lip materials etc. Care must be taken when increasing the lip length due to the possibility of it twisting on the shaft. Application engineers should consult their seal manufacturer, if unsure of what style of lip to use.

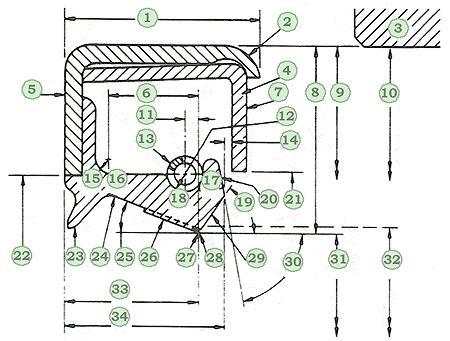

Lip Seal Glossary

1. Case Width

2. Outer Case

3. Housing

4. Inner Case

5. Outside Face

6. Lip Length

7. Inside Face

8. Radial Wall Dimension

9. Seal Outer Diameter

10. Housing Bore

11. Spring Axial Position

12. Spring Groove

13. Garter Spring

14. Axial Clearance

15. Heel Section

16. Flex Thickness Area

17. Spring Retaining Lip

18. Head Section

19. Inside Lip Angle

20. Toe Face

21. Inside Face Inner Diameter

22. Outer Case Inner Diameter

23. Secondary Lip

24. Outside Lip Surface

25. Airside Lip Angle

26. Rib (Hydrodynamic Seal Only)

27. Contact Line

28. Static Lip

29. Fluidside Lip Surface

30. Molded Toe Angle

31. Lip Diameter

32. Unsprung Lip Diameter

33. Contact Line Height

34. Lip Height

Another key design feature in the design of a rotary seal lip is the angle on both sides of the interface where the seal lip and shaft contact. In general, it is recommended that rotary seal lips be designed with a fluid side angle that is greater than the airside angle. Fluid side angle – angle between the side of the sealing lip facing the fluid being sealed, and the shaft. Airside angle – angle between the side of the sealing lip facing away from the fluid being sealed, and the shaft. If a seal is installed backward, the airside lip angle will be greater than the fluid side angle creating a situation where more fluid is pumped towards the contact zone resulting in leakage. When influenced by shaft finish, fluid viscosity, temperature, and radial load, the fluid side angle creates a pressure gradient that is greater than the air side pressure gradient. This helps create a condition where more fluid is pumped away from the contact zone than towards it. Under RMA standards, the shaft is finished to not leave any screw grooves from the machining process. This is called plunge grinding. Shaft finish is important because as the shaft rotates it will wear away a little rubber from the seal tip. If the shaft is too smooth, then not enough lip abrasion will occur. If the shaft is too rough, then excessive wear will occur. As optimal wear occurs, mircoaspreties will form on the seal lip. Microaspreties – microscopic pores that develop on an elastomeric sealing lip as a result of wear caused by a rotating shaft. Microaspreties hold lubrication and facilitate a pumping action that prevents leakage. As the shaft rotates, the microasperities are stretched in a circular direction at an angle to the shaft, creating a mini helix. When influenced by the lip angle, shaft speed, fluid viscosity and other operational characteristics these miniature helixes create an inward “pumping” action that pushes fluid back into the reservoir. Helixes can also be molded onto the rotary seal lip during the manufacturing process creating a hydrodynamic seal. Hydrodynamic seals are specially designed seals that feature helical ribs, cross-etched designs or grooves molded onto the airside of an elastomeric sealing lip. These helicies force fluid back into the reservoir. Typically used in unidirectional shaft rotations. The helix designs are typically ribbed, pads or other cross-etched designs. Because of the vacuum created by high pump rates, helixical designs also push contaminants toward the seal lip which may increase lip and shaft wear. In addition, helixical designs should only be used on shafts rotating in one direction. Reversing the shaft rotation will cause leakage because the pumping action is reversed causing fluid to be pumped out of the sump. In addition, installing a seal backward will also cause significant leakage because the pumping action will now be away from the reservoir. To facilitate a bidirectional shaft, it is recommended that triangular pads be molded onto the lip. Finally, some rotary seal designs also include the use of a non-spring-loaded secondary sealing lip. The secondary sealing lip is typically used to exclude airside contaminants.

Secondary lips are generally smaller in size but have a larger diameter than the primary lip and are located in the heel of the beam (the opposite of the primary lip head). Secondary sealing lips can have an axial or radial orientation to the shaft. Axially oriented secondary sealing lips will require a wall or flange to seal against and are used in applications that require superior dirt exclusion. Radial oriented secondary sealing lips seal against the shaft and generally exclude light dust and contaminants. Rotary seal lip design is influenced by numerous operational and design factors. Application designers should consult their seal suppliers for seal design recommendations for their applications. If you have any questions or require further information on what type of seal to use for your application, contact Colonial Seal Company at 1.800.564.2201 or email sales@colonialseal.com.

Founded in 1994, Colonial Seal Co. is headquartered in Westville, New Jersey. Colonial Seal specializes in oil & grease seals, hydraulic seals, rotary shaft seals, mechanical seals, rubber molded products and gaskets. Through a global network of manufacturers, Colonial Seal can produce custom seals designed for a client’s unique sealing applications. Colonial Seal Company is ISO 9001:2008 certified.